A matrix tray holder is a fixture used in Surface Mount Technology (SMT) production to securely present components packaged in standard matrix or waffle trays to a pick-and-place machine.

Key Features and Benefits

Component Versatility: Matrix tray holders are essential for handling large, delicate, or odd-shaped components like BGAs, QFPs, connectors, and some LEDs that are unsuitable for tape-and-reel feeders.

ESD Protection: The trays themselves are made from conductive materials to provide reliable electrostatic discharge (ESD) protection, safeguarding sensitive components during all stages of handling, testing, and shipping.

Standardization: Many trays and holders adhere to JEDEC global standards for X and Y dimensions (typically 12.6in x 5.3in), ensuring interchangeability across different equipment and manufacturers.

Improved Accuracy: They ensure components are presented in a repeatable and accurate manner, which is crucial for fine-pitch components and reduces placement errors.

Delivery lead time : in stock

Payment : TT , PayPal, CreditCard, Western Union

MOQ : 1PCS

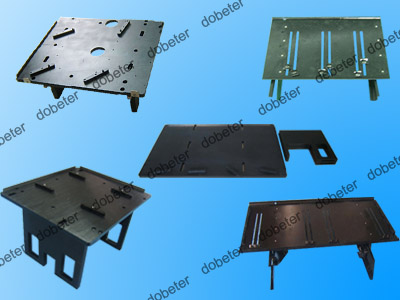

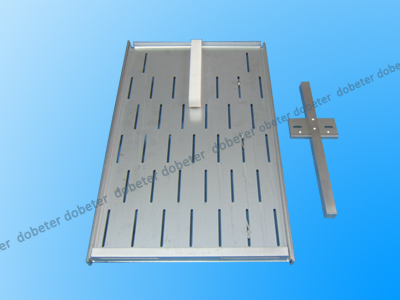

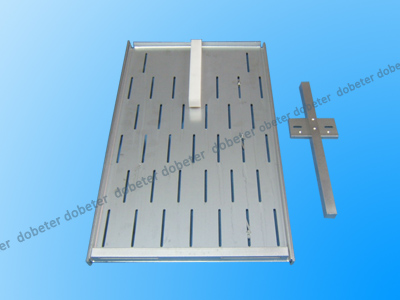

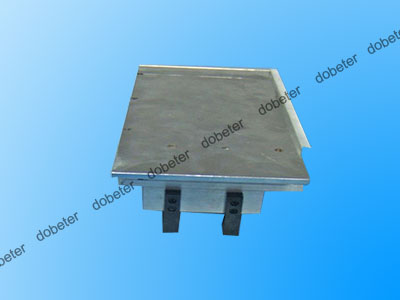

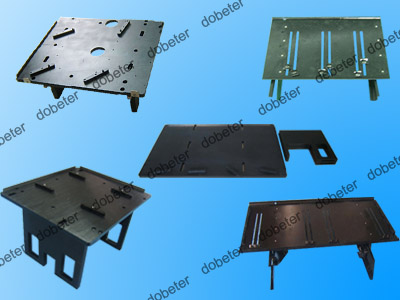

Products

Products